Mutuwar Casting

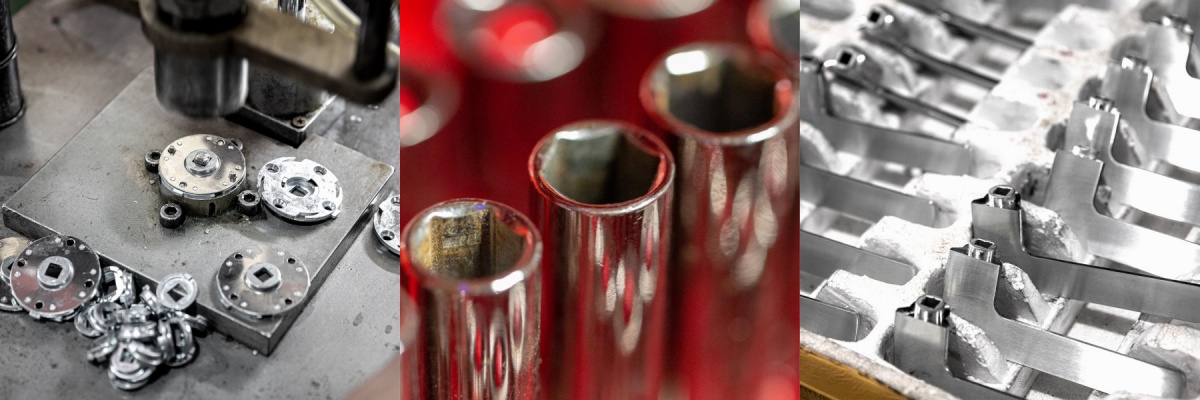

Tsarin simintin mutuwa shine a danna narkakkar karfe zuwa wani gyaggyarawa a karkashin babban matsi don samar da hadaddun sifofi daban-daban na sassan kayan aikin kofa. Ana buƙatar kammala wannan tsari cikin kankanin lokaci don hana ƙarfe daga sanyi da ƙarfafawa. Bayan an yi allurar karfen ruwa a cikin kwandon, yana buƙatar sanyaya kuma a ƙarfafa shi. Ana aiwatar da aikin sanyaya yawanci a cikin ƴan daƙiƙa zuwa ƴan mintuna, dangane da girma da siffar ɓangaren. Bayan sanyaya, za a cire ɓangaren daga cikin ƙirar kuma a sarrafa shi daga baya.

Machining

Wuraren da aka cire da simintin gyare-gyaren da aka mutu yawanci suna buƙatar wasu hanyoyin aiwatarwa, irin su ɓarna, jiyya na ƙasa, injina (hakowa, tapping), da sauransu. Waɗannan hanyoyin suna iya haɓaka ingancin farfajiya da daidaiton girman sassan don biyan buƙatun ƙira.

CNC (Kwamfuta Kula da Lambobi)

Tsarin CNC yana amfani da shirye-shiryen kwamfuta don sarrafa motsi da aiki na kayan aikin injin, kuma yana iya dacewa da daidai daidai da kammala sassa daban-daban, niƙa, juyawa, hakowa da sauran ayyukan sarrafawa don sassan kayan aikin kofa.

Kayan aikin injin CNC na iya ci gaba da gudana ba tare da sa hannun ɗan adam ba, yana haɓaka ingantaccen samarwa. Lokacin aiki na sassa masu rikitarwa yana raguwa sosai, kuma an rage yawan sake zagayowar samarwa.

Ta hanyar canza shirye-shirye da kayan aiki, kayan aikin injin CNC na iya daidaitawa da sauri ga bukatun sarrafawa na sassa daban-daban. Wannan sassauci yana sa tsarin CNC ya dace da ƙananan ƙananan, samfurin samar da abokin ciniki na musamman.

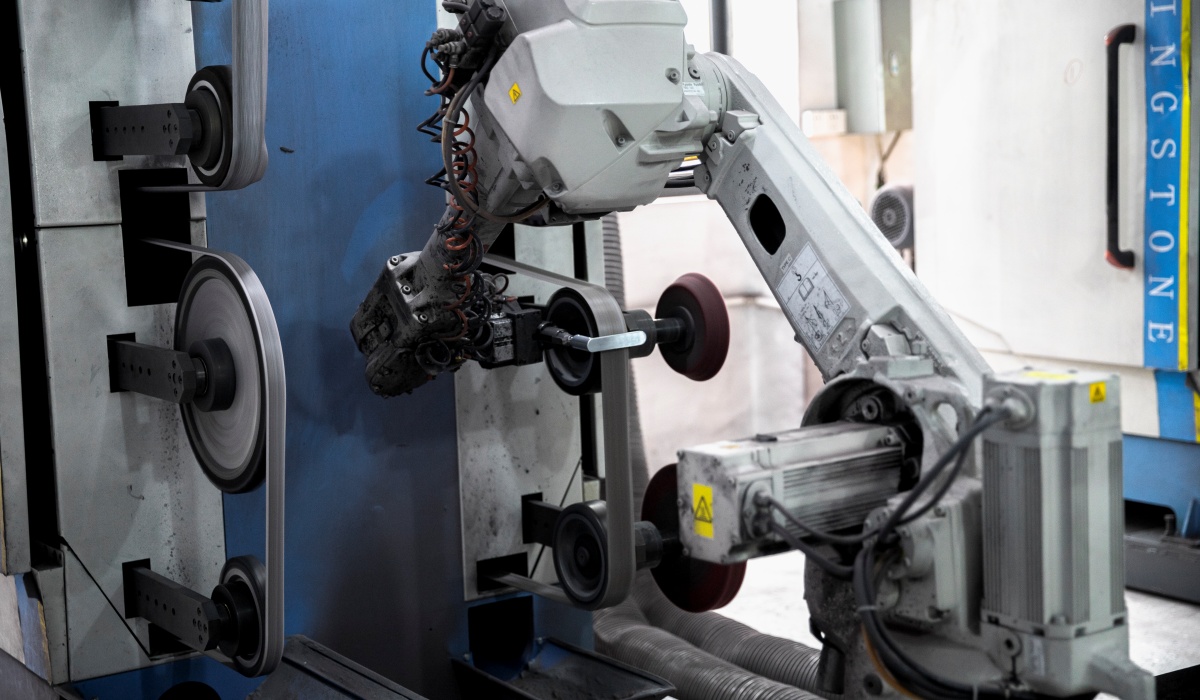

goge baki

goge goge yana da mahimmanci koyaushe. Muna da namu shuka polishing tare da kusan 15 gogaggen ma'aikata. Da farko, muna amfani da bel mai kauri (babban hatsi) don goge “flashes” da “alamomin ƙofa”. Abu na biyu, muna amfani da lallausan bel (ƙananan hatsi) don goge surar. A ƙarshe muna amfani da dabaran auduga don goge saman mai sheki. Ta wannan hanyar, electroplating ba zai sami kumfa na iska da raƙuman ruwa ba.

Tsarin jiyya na saman: electroplating / fesa fenti / anodization

Bayan da ƙazantar da ke saman samfurin kayan aikin, lokaci ya yi da za a ƙara launi. Ana kiran wannan tsari "electrolating" kuma samfurin da aka yi wannan tsari shi ake kira electroplated parts.

Majalisa

Haɗin hannu da tushe: Haɗa ɓangaren hannu da tushe tare da screws ko buckles, kuma tabbatar da cewa haɗin tsakanin kowane bangare yana da ƙarfi kuma ba sako-sako ba.

Gwajin aiki: Bayan taro, yi gwajin aiki akan hannun ƙofar don tabbatar da cewa juyawa, canzawa da sauran ayyukan suna da santsi kuma babu cunkoso.